2023.11.23

2023.11.23Fiber optic connectors were once unwieldy and difficult to use. With the standardization and simplification of fiber optic connectors by manufacturers, the fiber optic connectors with better performances are more convenient to use. The increasing user-friendliness has contributed to the increase in the use of fiber optic systems. This tutorial will briefly analyze today's fiber optic connectors market and give an in-depth introduction about fiber connectors.

A Brief Analysis of Fiber Optic Connector Market

In recent years, the global marketplace has been driven by the increasing adoption of fiber optic technology. Fiber optic cables are widely used to replace copper cables in most cases, which have a positive impact on the fiber optic connector market. The following bar chart from Grand View Research shows the development of fiber optic connector types like LC, SC, MTP fiber connectors in recent years.

Figure1: Fiber Optic Connector Market

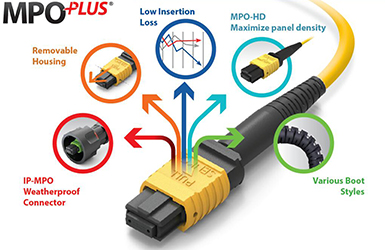

From the chart, it's easy to know that the increase of these five commonly-used fiber optic connectors has a steady tendency; specifically speaking, LC connectors still domains the major optical connector market in the next years, and the need for MTP/MPO connectors are also growing recently, which indicates that the MTP/MPO connectors may tend to occupy more market share.

In conclusion, the total growing trends have reflected the constant demands for fiber connectors. And the market is witnessing the development of fiber optic connectors. High-density and high-quality connectors like LC connectors still remain the first choice for many users. And the multi-fiber optical connectors like MTP/MPO connectors or even the Rosenberger Q-RMC connectors may gain more favors due to the popularity of the high-bandwidth 100G/200G/400G network deployments and 5G applications. We can anticipate that as the growing demand for efficient cabling and cable management, fiber optic connectors that can provide easy installation, low fiber loss, and high performance will continue to be the trend in optical communications.

Fiber Optic Connector Archives

What's Fiber Optic Connector?

Fiber optic connector, or optical fiber connector, is a component to terminate the end of fiber optic cable and enables quicker connection and disconnection than fiber splicing. It mechanically couples and aligns the fiber cores to make light pass successfully. Therefore, fiber optic connectors have an important impact on the fiber optic transmission reliability and the performance of the system. Normally speaking, high-quality optical connectors will lose very little light due to the reflection or misalignment of the fibers.

Figure2: LC Fiber Optic Connector

Standards for Fiber Optic Connectors

As an optical component, fiber optic connectors comply with several standards in telecommunications cabling or electrical engineering fields. Here is a table that provides part of the standards that fiber optic connectors accord with:

| TIA/EIA | Telcordia | IEEE |

|---|---|---|

| TIA/EIA-4750000-B: Generic Specification for Fiber Optic Connectors |

GR-326: Generic Requirements for Single Mode Optical Fiber Connectors |

IEEE Ethernet protocol standard 802.3: for Carrier Sense Multiple Access with Collision Detection (CSMA/CD) Access Method and Physical Layer Specifications |

| TIA/EIA-604: Fiber Optic Connector Intermateability Standards (FOCIS) |

GR-1435: Generic Requirements for Multi-fiber Optical Connectors |

IEEE standard 802.3ae: for 10 Gigabit Ethernet over Optical Fiber (single mode and multimode) |

| TIA/EIA-568-B.3/C.0/C.3: Commercial Building Fiber Optic Standards |

/ | IEEE standard 802.3aq: for 10 Gigabit Ethernet over Installed Multimode Optical Fiber up |

What's the Structure of Fiber Optic Connectors?

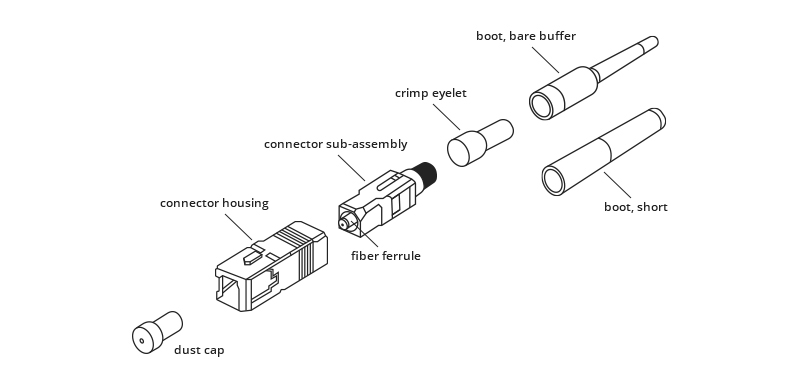

For an optical connector design, there are five key and important components: the fiber ferrule, the sub-assembly body, the connector housing, the fiber cable, and the stress relief boot. We'll take an SC connector for example to illustrate the structure of the fiber optic connector.

-

Fiber Ferrule

The SC fiber optic connector is built around a long cylindrical 2.5mm diameter ferrule, made of ceramic (zirconia) or metal (stainless alloy). A 124um-127um diameter high precision hole is drilled in the center of the ferrule, where stripped bare fiber is inserted through and usually bonded by epoxy or adhesive. The end of the fiber is at the end of the ferrule, where it is typically polished smooth.

-

Sub-assembly Body

The ferrule will be assembled in the SC sub-assembly body that has mechanisms to hold the cable and fiber in place. The end of the ferrule is out of the sub-assembly body in order to mate with another SC connector inside a mating sleeve (i.e. adapter or coupler).

-

Connector Housing

Then the fiber optic connector housing will cover the connector sub-assembly body, which provides the mechanism for snapping into a mating sleeve (adapter) and holding the connector in place.

-

Fiber Cable

Fiber cable and strength member (aramid yarn or Kevlar) are crimped onto the connector sub-assembly body with a crimp eyelet, increasing the strength of the mechanical handling of the connector while protecting the fiber inside at the same time.

-

Stress Relief Boot

Stress relief boot covers the joint between the connector body and fiber cable to protect the fiber cable from mechanical damage. Stress relief boot designs are different for 900um tight-buffered fiber and 1.6mm-3mm fiber cable.

Figure3: Structure of Fiber Optic Connectors

Key Features of Fiber Optic Connectors

The key characteristics of the fiber connectors include optical properties, interchangeability, repeatability, reliability, insertion times, etc.

-

Optical Properties: insertion loss and return loss are the two main parameters for the optical properties. The lower the insertion loss value, the better. Normally, a qualified connector should keep the insertion loss value below 0.5dB. Contrariwise, a higher return loss will indicate better performance of the connector. The typical value of the connector's return loss should not be less than 25dB, while practically not less than 45dB on account of the polishing process. The reference to Insertion Loss and Return Loss for Fiber Connectors will illustrate these two parameters of fiber optic connector for you.

-

Interchangeability and Repeatability: Fiber optic connectors are universal passive devices, the fiber connector of the same type, can be used in any combination and can be used repeatedly.

-

High reliability: Outside plant applications may require fiber connectors to be located underground or outdoor walls. High-reliability fiber connectors are needed in these harsh environments to make sure of smooth optical transmission.

-

Utilization Rate: Can be plugged more than 1,000 times generally. Therefore, a fiber connector that is easy to use will help users save lots of installation time and improve working efficiency.

Fiber Optic Connector Types

Based on different classification methods, fiber optic connectors can be divided into different types. According to the pin end surface of the connector, they can be divided into PC, UPC, and APC. According to the different transmission media, fiber connectors can be divided into single mode and multimode fiber optic connectors. Multiple fiber optic connectors have been introduced to the market, but only a few represent the majority of the market, like LC, SC, FC, ST, and MTP/MPO connectors.

Figure4: Fiber Optic Connector Types

The above optical connectors types are common fiber optic connectors that require an adapter panel for connecting, which are widely used in data centers, telecom rooms, server farms, cloud storage networks and so on. However, the two new and robust industrial connectors from Rosenberger, namely Q-RMC and NEX10 fiber optic connectors, use Push-pull Quick Lock design for easy installation. Both Q-RMC and NEX10 connectors are designed for harsh environment use, which is recommended to apply in industrial sites, mine fields, mobile communication (FTTA), 5G base station and so on. Click here to get a comprehensive introduction of the fiber optic connector types.

Figure5: Rosenberger Connector Types

Fiber Connector Coupling Loss

Only the light that is coupled into the receiving fiber's core will propagate, while the rest of the light is not transmitted through the splice and is radiated out of the fiber. Ideally, the loss will be minimized if the two fiber cores are identical and perfectly aligned, the connectors or splices are properly finished and no dirt is present. Unfortunately, both the fiber and connector are subject to manufacturing tolerances that create less than perfect alignment.

Connector and splice loss is caused by many factors. For example, end gaps will influence insertion loss and return loss. Therefore, optical connectors will adopt a number of polishing techniques to insure physical contact of the fiber ends to minimize back reflection. In addition, light from a fiber with a larger numerical aperture (NA) will be more sensitive to angularity and end gap, so transmission from a fiber of larger NA to one of smaller NA will be higher loss than the reverse. In other words, connecting larger fibers to smaller ones results in substantial losses, not only due to the smaller cores size, but also the smaller NA of most small core fibers.

Fiber Optic Connector Applications

Fundamentally speaking, the fiber optic cables with optical connectors are mainly used in telecom communication fields, from small or middle-sized offices to hyper-scale data centers. As the following figure shows telecom accounted for the largest market share in terms of revenue. Furthermore, increasing demands of 5G networks, 100/200/400G high-speed transmission, and cloud-based applications will also stimulate demand. There is still a continued rise in global demand from the burgeoning IT industry regarding the availability of power-efficient, cost-effective, and high-level network infrastructure.

Besides, the oil & gas, military & aerospace, and medical application segments are poised to witness significant growth rates, owing to the increasing adoption of multimode and Plastic Optical Fiber (POF) across these application segments. For instance, military forces use the optical connector technology for a wide variety of ground, sea, air, and space solicitations, such as in avionics testing equipment modules and ground support systems in fighter planes.

Figure6: Fiber Optic Connector Applications

FAQs

For 125um fibers, should I choose a 125.5um or 126um hole ferrule? What's the difference?

126um is the recommended ferrule hole size for 125um single mode fiber. There are some 125.5um ferrules available for critical alignment situations, but the 126um hole allows some epoxy bond around the fiber for the fiber insertion without breakage.

How are the fiber connectors tested?

Typically speaking, the tests are twofold: field testing and factory testing. The factory testing may use a profiling system to ensure the correctness of the overall polished shape of the fiber optic connectors. An optical microscope may be used to observe blemishes. Field testing involves the use of a special hand-held optical microscope for checking dirt and blemishes, as well as certain other tests to examine the parameters.

How to choose a proper fiber connector?

Fiber patch cables can be purchased with different configurations (SC-SC, SC-LC, etc.). The type of equipment you are installing will determine the needs of your fiber optic connectors. There are also various adapters and patch cable configurations that can be utilized to connect fiber optic-based equipment.

When and how to clean fiber optic connectors?

Whenever the connector is not terminated, it should be covered to protect the end of the ferrule from dirt. Before connection and testing, it is advisable to clean both ends with lint-free wipes moistened with isopropyl alcohol. There are special solvents, wipes, and swabs for the cleanliness, following the manufacturer's cleaning instructions is a wise choice. Fiber Connector Cleaning Tutorial will guide you to clean the fiber optic connectors.